Cast aluminum panels were developed with the fine art foundry Polich Tallix. The research began with experiments in which various wire meshes, textiles, and fabrics were added to sand casting molds to alter the texture and color of the aluminum. The final cast is the result of an organic burlap that burns away, leaving the trace of a fine fabric texture on the surface of the aluminum.

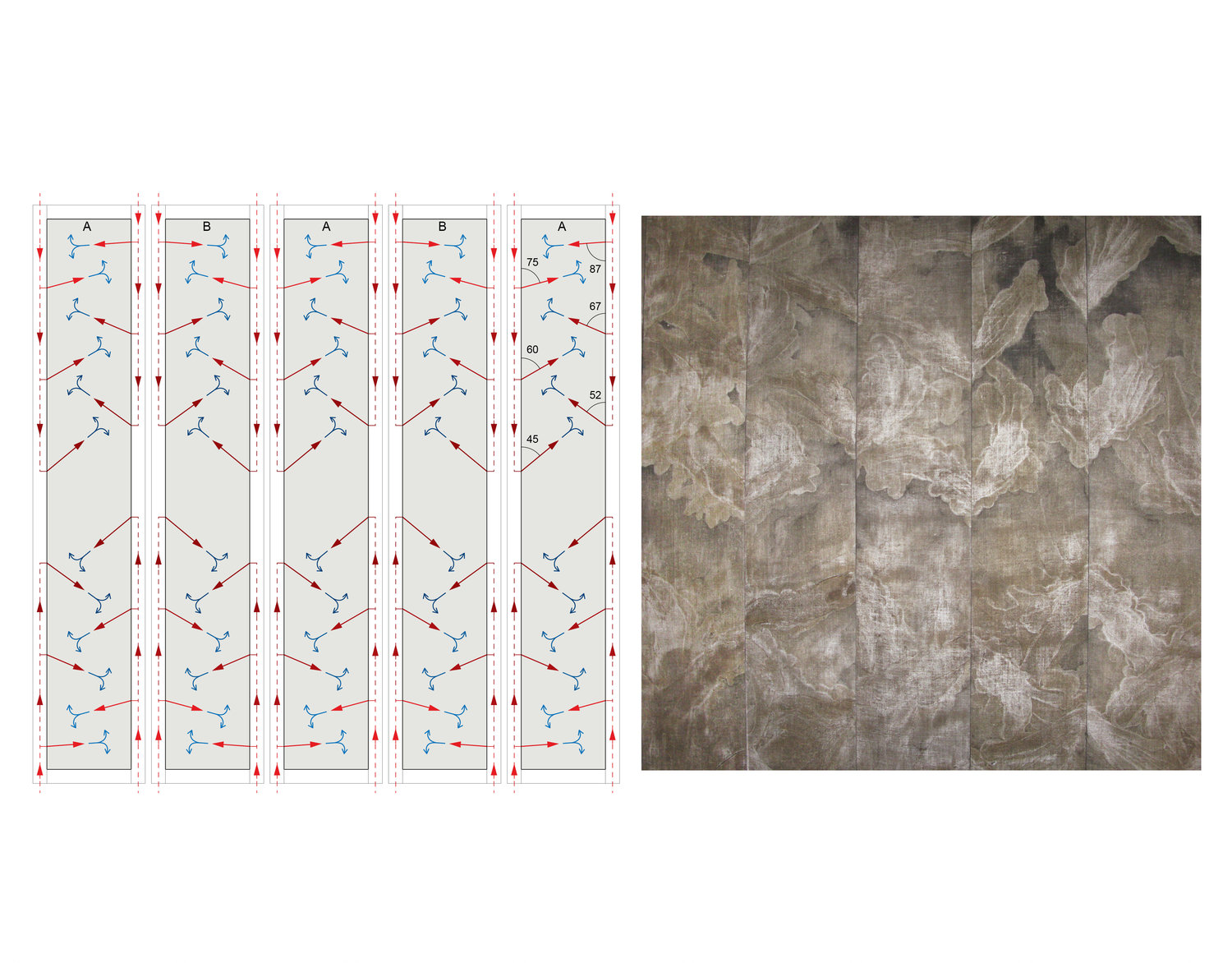

More dramatic is the pronounced change in color due to the combustion of the burlap. Entering the mold at extremely high temperatures, the molten aluminum burns the burlap quickly, leaving brighter tones of white, silver, and gold. As the remainder of the mold eventually fills, the aluminum cools resulting in darker greys and blacks. These color shifts were enhanced by the discovery that the directions the aluminum flowed within the mold were extremely consistent.

Through the natural process of casting over burlap, the color alterations due to temperature, and the natural flow direction, a repeatable pattern was established. Adjacent molds were mirrored to allow the pattern to extend from panel to panel. At the foundry, over 650 panels were book-matched by hand, reinforcing a spatial unraveling of the installation.

Material Research with Polich Tallix

More dramatic is the pronounced change in color due to the combustion of the burlap. Entering the mold at extremely high temperatures, the molten aluminum burns the burlap quickly, leaving brighter tones of white, silver, and gold. As the remainder of the mold eventually fills, the aluminum cools resulting in darker greys and blacks. These color shifts were enhanced by the discovery that the directions the aluminum flowed within the mold were extremely consistent.

Through the natural process of casting over burlap, the color alterations due to temperature, and the natural flow direction, a repeatable pattern was established. Adjacent molds were mirrored to allow the pattern to extend from panel to panel. At the foundry, over 650 panels were book-matched by hand, reinforcing a spatial unraveling of the installation.

Material Research with Polich Tallix